1) Material type - Aluminum. Doesn't matter what kind. Whatever is cheapest

2) Is a material quote required or is material supplied - Include material in quote

3) Quantity - (4)

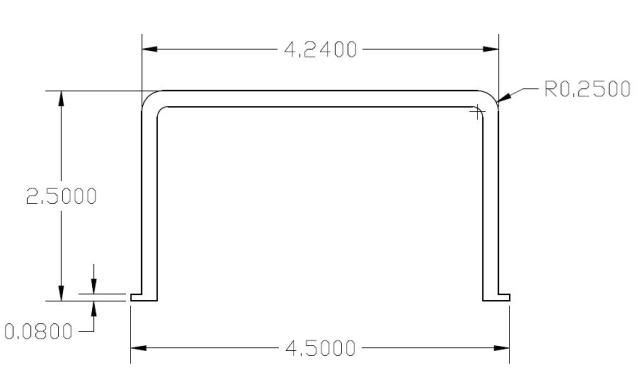

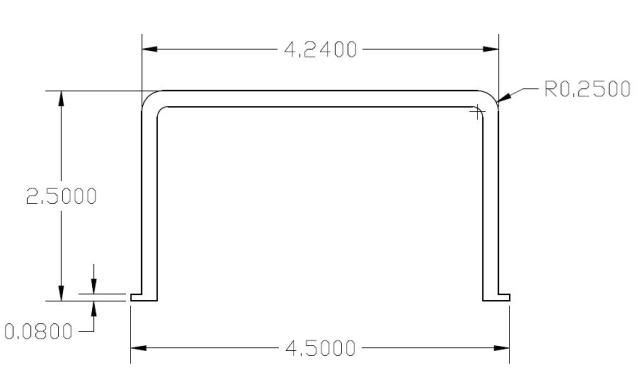

4) Drawings should be immediately available or necessary specs. - I have 2D and 3D drawings of this part. Email me for them.

5) Required time frame - 2-3 weeks

6) RFQ ending time - bid closes 5-15-09

These are center caps. Parts to be turned, then Anodized black, then the logo machined into the face.

3D render:

email quotes to jesscneal@yahoo.com

Thanks!

Jess

2) Is a material quote required or is material supplied - Include material in quote

3) Quantity - (4)

4) Drawings should be immediately available or necessary specs. - I have 2D and 3D drawings of this part. Email me for them.

5) Required time frame - 2-3 weeks

6) RFQ ending time - bid closes 5-15-09

These are center caps. Parts to be turned, then Anodized black, then the logo machined into the face.

3D render:

email quotes to jesscneal@yahoo.com

Thanks!

Jess